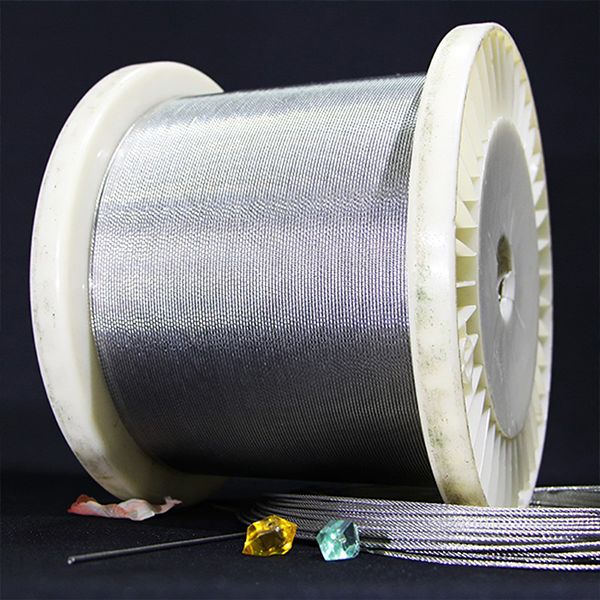

Usha birta ah ee aan lahayn birta ah ee Ultra khafiif ah

Hordhac Silig Bir ah

Heerka birta: Bir

Heerarka: AISI, ASTM, BS, DIN, GB, JIS

Asal ahaan: Tianjin, Shiinaha

Nooca: Birta

Codsiga: warshadaha, qalabka wax soo saarka, lowska iyo boolal, iwm

Daawaha ama maya: aan daawaha lahayn

Ujeeddo gaar ah: bir jaritaan bilaash ah

Moodel: 200, 300, 400, taxane

Magaca summada: zhongao

Heerka: bir aan daxal lahayn

Shahaadada: ISO

Tusmada (%): ≤ 3% Tusmada Si (%): ≤ 2%

Cabbirka silig: 0.015-6.0mm

Tusaale: waa la heli karaa

Dhererka: 500m-2000m / giraangiraha

Dusha sare: dusha sare oo dhalaalaya

Astaamaha: iska caabbinta kulaylka

Sawir-gacmeedka siligga birta aan lahayn (sawir-gacmeedka siligga birta aan lahayn): hab-raac farsamayn oo balaastig bir ah oo ul siligga ah ama siligga bannaan laga soo qaadayo godka siligga ee dice-ka dice-ka iyadoo la adeegsanayo xoog sawir-qaadis si loo soo saaro siligga birta ah ee qayb yar ama siligga birta aan birta ahayn. Fiilooyinka leh qaabab kala duwan oo isgoys ah iyo cabbirro biraha iyo birta kala duwan ah waxaa lagu soo saari karaa sawir-qaadis. Siligga la sawiray wuxuu leeyahay cabbirro sax ah, dusha siman, qalab sawir fudud iyo qaabab, iyo wax-soo-saar fudud.

Bandhigga Alaabta

Astaamaha Habka

Xaaladda walbahaarka ee sawir-gacmeedka siligga waa xaaladda walbahaarka ugu weyn ee saddex-geesoodka ah ee cadaadiska cadaadiska laba-geesoodka ah iyo cadaadiska hal-geesoodka ah. Marka la barbardhigo xaaladda walbahaarka ugu weyn halkaas oo dhammaan saddexda jiho ay yihiin cadaadis cadaadis, siligga birta la jiiday way fududahay in la gaaro xaaladda isbeddelka balaastikada ah. Xaaladda isbeddelka ee sawirku waa xaalad isbeddel weyn oo saddex-geesood ah oo ah isbeddel cadaadis laba-geesood ah iyo isbeddel hal-geesood ah. Xaaladdani ma fiicna balaastikada agabka birta, waana ay fududahay in la soo saaro oo la soo bandhigo cilladaha dusha sare. Tirada isbeddelka gudbinta ee habka sawir-gacmeedka siligga waxaa xaddidaya qodobka badbaadada, iyo inta yar ee isbeddelka gudbinta, sawirku wuu sii gudbayaa. Sidaa darteed, marinno badan oo sawir-gacmeed xawaare sare leh oo joogto ah ayaa badanaa loo isticmaalaa soo saarista siligga.

Kala duwanaanshaha Dhexroorka Wire

| Dhexroorka silig (mm) | Dulqaadka Xu (mm) | Dhexroorka leexashada ugu badan (mm) |

| 0.020-0.049 | +0.002 -0.001 | 0.001 |

| 0.050-0.074 | ±0.002 | 0.002 |

| 0.075-0.089 | ±0.002 | 0.002 |

| 0.090-0.109 | +0.003 -0.002 | 0.002 |

| 0.110-0.169 | ±0.003 | 0.003 |

| 0.170-0.184 | ±0.004 | 0.004 |

| 0.185-0.199 | ±0.004 | 0.004 |

| 0.-0.299 | ±0.005 | 0.005 |

| 0.300-0.310 | ±0.006 | 0.006 |

| 0.320-0.499 | ±0.006 | 0.006 |

| 0.500-0.599 | ±0.006 | 0.006 |

| 0.600-0.799 | ±0.008 | 0.008 |

| 0.800-0.999 | ±0.008 | 0.008 |

| 1.00-1.20 | ±0.009 | 0.009 |

| 1.20-1.40 | ±0.009 | 0.009 |

| 1.40-1.60 | ±0.010 | 0.010 |

| 1.60-1.80 | ±0.010 | 0.010 |

| 1.80-2.00 | ±0.010 | 0.010 |

| 2.00-2.50 | ±0.012 | 0.012 |

| 2.50-3.00 | ±0.015 | 0.015 |

| 3.00-4.00 | ±0.020 | 0.020 |

| 4.00-5.00 | ±0.020 | 0.020 |

Qaybta Badeecada

Guud ahaan, waxa loo qaybiyaa 2 taxane, 3 taxane, 4 taxane, 5 taxane iyo 6 taxane bir ah oo aan daxal lahayn sida waafaqsan austenitic, ferritic, laba-geesood ah bir ah oo aan daxal lahayn iyo martensitic bir ah oo aan daxal lahayn.

Birta aan miridhku lahayn ee 316 iyo 317 (fiiri sifooyinka birta aan miridhku lahayn ee 317) waa bir aan miridhku lahayn oo ay ku jiraan molybdenum. Waxyaabaha ku jira molybdenum ee birta aan miridhku lahayn ee 317 waxay ka yar tahay tan birta aan miridhku lahayn ee 316. Sababtoo ah molybdenum-ka birta ku jira, waxqabadka guud ee birtan ayaa ka wanaagsan birta aan miridhku lahayn ee 310 iyo 304. Xaaladaha heerkulka sare, marka fiirsashada aashitada sulfuric ay ka hooseyso 15% oo ay ka badan tahay 85%, 316 Bir aan miridhku lahayn waxay leedahay isticmaallo kala duwan. Bir aan miridhku lahayn ee 316 sidoo kale waxay leedahay iska caabin wanaagsan oo ku wajahan daxalka chloride, sidaa darteed waxaa badanaa loo isticmaalaa deegaannada badda. Bir aan miridhku lahayn ee 316L waxay leedahay kaarboon ugu badan oo ah 0.03, kaas oo loo isticmaali karo codsiyada aan la samayn karin daxalka ka dib alxanka iyo iska caabinta ugu badan ee daxalka.